Advancing Automation: Material Handling Robotics Market Analysis and Regional Perspectives

|

| Material Handling Robotics Market |

The Material Handling Robotics Market refers to the industry

segment focused on the development, implementation, and utilization of robotic

systems and solutions for handling materials and goods across various sectors.

These robotics systems are designed to automate tasks such as picking, packing,

sorting, and transporting items, thereby enhancing efficiency, accuracy, and

productivity in material handling operations.

The material handling robotics market is estimated to be

valued at USD 24.21 Bn in 2024 and

is expected to reach USD 49.04 Bn by

2031, growing at a compound annual growth rate CAGR of 10.6% from 2024 to 2031.

Market Key

Trends:

Several key trends are shaping the Material

Handling Robotics Market. Firstly, there is a notable trend towards the

integration of artificial intelligence (AI) and machine learning algorithms in

robotic systems, enabling advanced decision-making capabilities and autonomous

operation. Secondly, the rise of collaborative robots (cobots) designed to work

alongside human operators is gaining traction, enhancing flexibility and safety

in material handling tasks. Additionally, the adoption of Internet of Things

(IoT) technologies for real-time data monitoring and predictive maintenance is

a prominent trend driving market growth.

Key Players

Key players operating in Material Handling Robotics Market

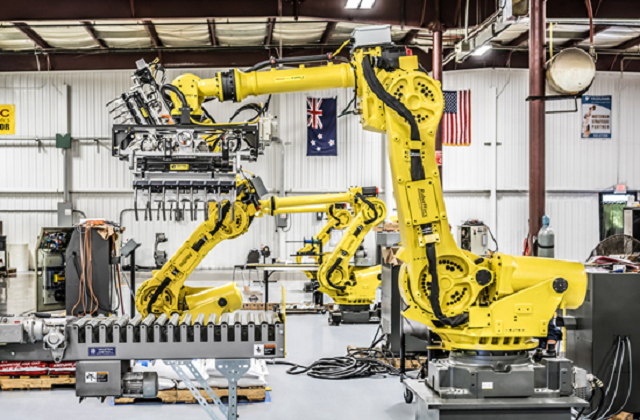

are ABB, Kuka AG, FANUC Corporation, Yaskawa Electric Corporation, Kawasaki

Heavy Industries Ltd., Universal Robots, Denso Corporation, Epson Robots,

Stäubli International AG, Omron Corporation, Nachi-Fujikoshi Corporation, Comau

S.p.A., Adept Technology, Inc, Bastian Solutions, Kanoo Machinery, ElectroMech

Industry Co, SSI SCHAEFER, Alesayi Heavy Equipment (AHE), Jugheinrich AG, and

Mitsubishi Heavy Industry Group.

Porter

Analysis:

Supplier

Power: Supplier power in the Material Handling Robotics Market

varies based on the availability of advanced robotic technologies and

components. Established suppliers with innovative solutions and strong R&D

capabilities have higher supplier power, while niche suppliers may focus on

specific segments or technologies.

Buyer

Power: Buyer power in the Material Handling Robotics Market is

influenced by factors such as demand volume, customization requirements, and

competitive pricing. Large buyers with significant material handling needs may

negotiate favorable terms, while smaller buyers may rely on standardized solutions

or seek cost-effective options.

Competitive

Rivalry: Competitive rivalry in the Material Handling Robotics

Market is intense, driven by continuous innovation, product differentiation,

and market consolidation. Key players compete based on technological

advancements, solution customization, service quality, and global reach,

leading to a dynamic and competitive market landscape.

Threat of

Substitutes: The threat of substitutes in the Material Handling Robotics

Market is relatively low, given the unique capabilities and efficiencies

offered by robotic systems in material handling operations. Alternative

solutions such as manual labor or traditional material handling equipment may

not match the speed, accuracy, and scalability of robotic solutions in certain

applications.

Threat of

New Entrants: The threat of new entrants in the Material Handling Robotics

Market is moderate to high, driven by technological advancements, lower

barriers to entry for software-based solutions, and market demand for

specialized robotics applications. New entrants may disrupt the market with

innovative offerings, partnerships, or niche market strategies, posing

challenges to established players.

Geographical

Regions:

The Material Handling Robotics Market is segmented

geographically into regions such as North America, Europe, Asia Pacific, Latin

America, and the Middle East and Africa. Each region presents unique

opportunities and challenges influenced by factors such as technological

adoption, industrial automation trends, regulatory environments, and market

demand for material handling robotics solutions.

Segment

Analysis:

The Material Handling Robotics Market can be segmented based

on various factors such as industry verticals (e.g., manufacturing, e-commerce,

healthcare), types of robotic systems (e.g., automated guided vehicles, robotic

arms, palletizing robots), and end-user applications (e.g., warehouse

automation, logistics, assembly lines). Each segment has distinct market

drivers, growth opportunities, and competitive dynamics, highlighting the

importance of segment-specific strategies and solutions in the material

handling robotics industry.

Comments

Post a Comment